Olympic Engineering, Ltd. – Case Study

Stepping Up Shoe-Manufacturing Machine Development with SOLIDWORKS Solutions

Olympic Engineering Ltd. is a leading international supplier of shoe-manufacturing machinery and equipment that chose to implement SOLIDWORKS Professional design, SOLIDWORKS PDM Professional product data management, and SOLIDWORKS Composer technical communication software solutions.

Olympic Engineering Ltd. is a leading international supplier of shoe-manufacturing machinery and equipment. Founded in 1969 and headquartered in Athens, Greece, Olympic designs and manufactures many of the critical systems that global shoe manufacturers use to automate the production and assembly of shoe components, including shoe molding, crimping, and lasting machines, as well as shoe upper assembly and humidifying products. The company is particularly well known for its expertise and specialization in the development of shoe upper shaping applications, resulting in numerous international patents. Olympic machines fully conform with CE standards and are distinguished for their safe operation, ergonomic design, high productivity, overall robustness, and reliable longevity. Until 2010, Olympic utilized AutoCAD® and Google SketchUp® 2D design tools to document its designs and generate engineering drawings to support component production, shoe assembly, and customer presentations. That’s when management realized that the company needed to upgrade its product development platform to take advantage of automation technologies and realize the benefits of developing its shoemanufacturing machinery in 3D, according to Managing Director Nick Triantafyllis. “We needed to streamline our design and R&D effort, accelerate our manufacturing and assembly processes, and improve the ways that we use and leverage design data,” Triantafyllis explains. “Over the years, we have built up a massive volume of design data and engineering drawings, which was really scary and intimidating from a data management standpoint. We believed that moving to 3D design and implementing a product data management [PDM] system would provide us with the opportunity to achieve our goals, integrate with our ERP [enterprise resource planning] system, and better leverage the value of our design data.” After investigating potential 3D solutions online, Olympic chose to standardize on SOLIDWORKS® product development solutions, implementing SOLIDWORKS Professional design, SOLIDWORKS PDM Professional™ product data management, and SOLIDWORKS Composer technical communication software. “We chose SOLIDWORKS solutions because the integration of its applications and the widespread use of the software gave us the best impression,” Triantafyllis recalls. “SOLIDWORKS is simply a cleaner, neater, and easier 3D development environment, and the ability to integrate PDM with our SoftOne® ERP system was also critically important.”

Faster, More Accurate Design Drives Greater Throughput

Since implementing SOLIDWORKS solutions in 2010, Olympic has not only shortened development time—cutting machine design cycles by 40 percent—the shoe-manufacturing machine provider has also realized improved design accuracy, resulting in fewer design errors, improved machine performance, and greater design and manufacturing throughput. “SOLIDWORKS has benefited our design effort in multiple ways, such as having access to large assembly design and surfacing tools,” notes Designer Manuel Saitakis. “With SOLIDWORKS software, designing a machine is easier, faster, and more accurate than in the past,” Triantafyllis adds. “We can try new approaches that were just not possible working in 2D. This has helped us become more cost-effective in product development because we can continue to work with and reuse our library of 3D components and subassemblies— helping us to improve safety and ergonomics, and increase design reuse by 50 percent—while enjoying the flexibility to make design changes quickly and easily.”

Improved Workflows, Revision Controls with PDM

By implementing SOLIDWORKS PDM Professional product data management software and integrating it with the company’s ERP system, Olympic has enjoyed improved product development and manufacturing workflows—with tighter revision and quality controls. These benefits, in turn, have contributed to the shoe machine manufacturer’s productivity improvements. “Everything that we do happens more quickly because of the connection between our PDM and ERP systems,” Triantafyllis stresses. “We know what we have in the warehouse, and where in the process a particular project is in terms of design and production. From order processing to customer delivery, everything progresses faster because this solid data foundation provides everyone in the company with the opportunity to access and utilize 3D design data.”

Efficient Product Documentation Development

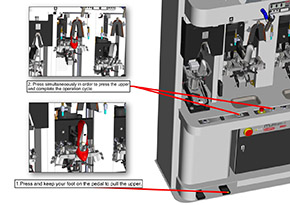

With the addition of SOLIDWORKS Composer technical communication software, Olympic has cut the amount of time required to produce user manuals and product documentation for its machines by 40 percent, while also being able to create specialized communications that have improved interactions with customers. “SOLIDWORKS Composer software enables us to leverage CAD data to efficiently create illustrations and images for manuals, catalogs, and our website; instructions for assembly and disassembly; and animations for performing maintenance, diagnostics, and trouble shooting tasks,” Triantafyllis explains. “When you combine all of the capabilities that SOLIDWORKS provides to complete functions more efficiently and costeffectively in-house, it’s easy to see that the move to SOLIDWORKS 3D is helping us to automate and grow our business,” Triantafyllis says. “That’s why we keep all of our licenses on subscription—so we have access to all the new features.”

CASE STUDY

The Challenge

Improve development processes and increase throughput for the design and production of automated shoe-manufacturing machines and equipment.

The Solution

Implement SOLIDWORKS Professional design, SOLIDWORKS PDM Professional product data management, and SOLIDWORKS Composer technical communication software solutions.

The Results

- Shortened machine design cycles by 40 percent

- Cut user manual development time by 40 percent

- Increased design reuse by 50 percent

- Improved product quality, safety, and ergonomics

Products(s) Used:

SolidWorks Enterprise PDM

SolidWorks Professional

SolidWorks Composer

With SOLIDWORKS software, designing a machine is easier, faster, and more accurate than in the past. We can try new approaches that were just not possible working in 2D. This has helped us become more cost-effective in product development because we can continue to work with and reuse our library of 3D components and subassemblies—helping us to improve safety and ergonomics, and increase design reuse by 50 percent— while enjoying the flexibility to make design changes quickly and easily.

With SOLIDWORKS Composer technical communication software and the SOLIDWORKS PDM Professional product data management system, Olympic Engineering has improved the quality of user manuals for its machines, automated its development workflows, and tightened its revision controls.Click edit button to change this text.